Guide of All in One Solar LED Street Lights(Updated in 2022)

1723L Series Square Luminous HighBay Light with Looped Optical Lens

View details

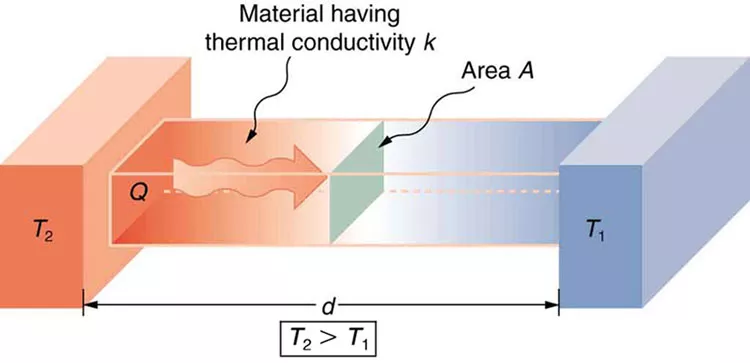

Thermal conductivity of various Metal materials:

Diamond: 2300 W/m.K Silver: 429 W/m.K

Copper: 401 W/m.K Gold: 317 W/m.K

Pure Aluminum: 237W/m.K Iron: 80 W/m.K

Tin: 67W/m.K Lead 34.8W/m.K

Our 200W~1000W High Mast LED Light use Copper Pipe + 1070 Stamping Aluminum Alloy Heatsink;

A / B / F Series LED Street Light use 6063 Extrusion Aluminum Alloy Heatsink;

C / D / E / F / H / I / J / T LED Street Light, LED Yard Lamp, LED Flood Light, Street Lamp Adapter, Use ADC12 Die-Casting Aluminum Alloy Heatsink.

A Series Solar Street Light use 6063 Extrusion Aluminum Alloy Heatsink; other series solar street light use Die-casting Aluminum heatsink.

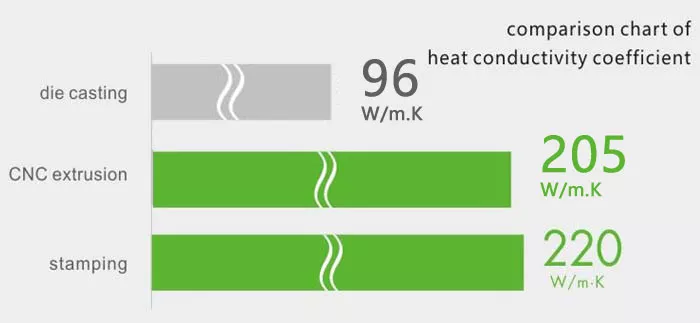

Comparison Chart of Heat Conductivity-Cofficient:

Material: Extrusion Aluminum – High Purity 6063 Aluminum Alloy, Aluminum Content:98.5%, High Quality Aviation Aluminum Alloy, thermal conductivity is 205W/m.K;

Material: Stamping Aluminum – High Purity 1070 Aluminum Alloy, Aluminum Content:99.7%, thermal conductivity is 226W/m.K ;

Material: Die-Casting Aluminum ADC12 / A380, Aluminum Content:85.5%, thermal conductivity is 97W/m.K;

Material: Die-Casting Aluminum A360 Aluminum Content:89.5%, thermal conductivity is 113W/m.K ;

1. Extrusion Aluminum Heat Sink Housing for Modular LED Street Light

High Purity, High Quality Aviation Aluminum, Main used in Modular Street Light, Good for Heat Dissipation, 5 Years Warranty.

2. Die-Casting Aluminum Heat sink Housing for LED Street Light.

Characteristic: Because the metal copper, zinc, aluminum and aluminum alloy have good fluidity and plasticity, and the casting process is cast in the pressure die casting machine, so the aluminum die casting can make a variety of more complex shapes, but also can make a higher precision and finish, thus greatly reducing the amount of mechanical processing of the casting and the casting allowance of metal copper, zinc, aluminum or aluminum alloy, which not only improves the quality of the casting As a result, die casting is widely used in automobile manufacturing because of its excellent thermal conductivity, small specific gravity and high machinabilityBecause the metal copper, zinc, aluminum and aluminum alloy have good fluidity and plasticity, and the casting process is cast in the pressure die casting machine, so the aluminum die casting can make a variety of more complex shapes, but also can make a higher precision and finish, thus greatly reducing the amount of mechanical processing of the casting and the casting allowance of metal copper, zinc, aluminum or aluminum alloy, which not only improves the quality of the casting As a result, die casting is widely used in LED Street Light, LED Flood Light, High Bay Light, Solar Street Lamp manufacturing because of its excellent thermal conductivity, small specific gravity and high machinability

Massive Fins 1070 Aluminum Heatsink, is Good for heat dissipation.

By riveting the copper heat pipe to Aluminum Fins has 20 times of heat transfer rate over pure aluminum radiator, which helps maximize the cooling area through a combination with the seamless fitting and Fin fastening, massive Fins technology;

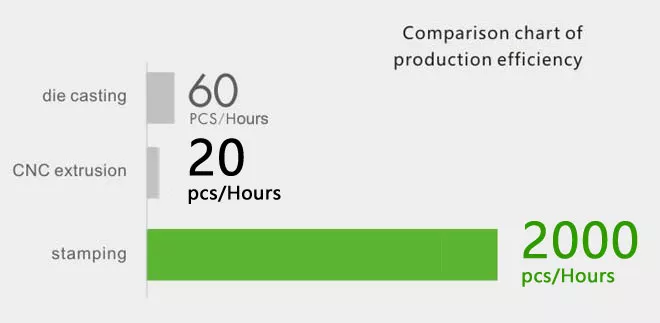

Comparison Chart of Production Efficiency:

Cost:

Stamping Aluminum is Expensive.

Die-Casting Aluminum is Cheap.

L Series Square Luminous HighBay Light with Looped Optical Lens

View detailsWHAT IS INTEGRATED ALL IN ONE SOLAR STREET LIGHT? and Components

View detailsLED Light Fixture heat dissipation, LED Street Light heatsink

View detailsWhy Do LED Street Lights Flicker?Solutions for flickering LED street lights

View details

HelloPlease log in